O.K. Engineers | Brass Components Manufacturer & Exporter of Brass & Copper Alloy Components

ISO 9001:2015 Certified Company

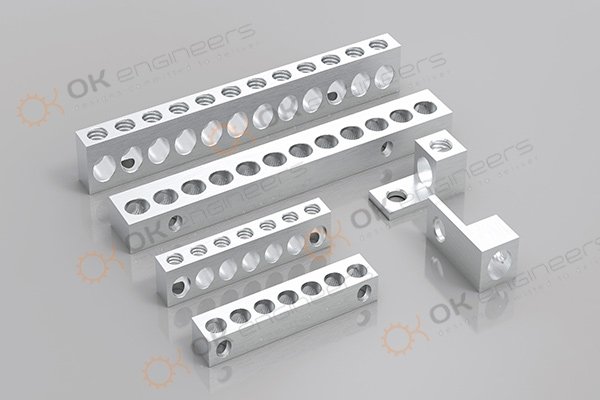

O.K. Engineers stands out as a leading Brass Components Manufacturer and exporter specializing in the production of top-quality brass and copper alloy components. With a steadfast commitment to precision engineering and unwavering quality, O.K. Engineers delivers an extensive array of high-grade components crafted from premium brass and copper alloys. Their proficiency lies in creating meticulously designed and impeccably finished brass components, catering to a wide spectrum of industries and applications. O.K. Engineers’ dedication to innovation and adherence to international standards ensures that their brass components, ranging from fittings to connectors and custom-designed parts, are not just reliable but also set a benchmark in the manufacturing and export of brass and copper alloy components worldwide.

No matter the size of the part or the complexity of design, here at O.K. Engineers you will find what you are looking for. We offer complex mill turning production and high quality finishing.

We are an established name among the industries as a brass precision turned parts manufacturer, supplier and exporter in Spain, Germany, USA, France, Russia, UK and worldwide.

Even a small imperfection in the brass precision turned component can lead to failure of the system, huge breakdown or hazards and to resolve this ambiguity of the thousands of industries, O.K. Engineers introduces a nonpareil assortment of brass precision turned parts, manufactured using the CNC machining technology and following the international quality controlled manufacturing methodologies. Our brass precision turned parts attributes precise design, dimensional precision, high tolerance, better surface finish and a truly seamless construction that guarantees for the unfailing operations everlastingly.

No other can deliver that sum of precision other than O.K. Engineers, as we have the newest technology, experience and skills to leverage and deliver second to none quality brass precision turned parts that promises for the seamless execution all through. Our huge inventory of the brass precision turned parts incorporates, cable glands for electrical & wiring industry, lamp parts for Lamp & Lighting Industry, Brass Reducers, Brass Enlarger, Brass Hydraulic and Pneumatic Fittings, Automotive components for Automobiles Industry, Brass Inserts for Moulding Industry, Brass Plumbing fittings for Sanitary ware Industries, Brass precision component, Brass Products for Hi-tech Applications as per specifications, drawing & samples.

Global Presence

One-stop Solution for Brass Precision Turned Parts:

From simple brass precision turned parts to intricate parts, O.K. Engineers is able to manufacture, supply and export a wide variety of brass products according to your specifications. O.K. Engineers manufactures precision turned parts as per customer drawings, no matter its low volume production, medium volume or high volume, we invariable embrace the philosophy of 100% cost benefit that reflects in our every piece of work.

PRODUCTS HIGHLIGHTS

Manufactured objects can be supplied after undergoing machining operations, Single spindle automatic bar turning machines, lathes, and second operation like milling, drilling & threading.

INFRASTRUCTURE

The expertise that we have developed with over 60 years of experience in an engineering industry is the basis of a successful family-run business that is now in its fourth generation.

COMPETENCY

Quality management Customer satisfaction and quality have always been our most important objectives.

QUALITY

WHY CHOOSE O.K. ENGINEERS? FOR Brass Components Manufacturer & Exporter of Brass & Copper Alloy Components

CNC TURNING TECHNOLOGY

Our single spindle CNC turning technology entitles combining of the manufacturing method in specific working stage, if there is any exclusive precision turned part requirements.

FAST PRODUCTION & ON TIME DELIVERY

We understand the downtime faced by the industries, just because of a tiny component of the system and thereby we dedicatedly accelerate ourselves to obtain the brass precision turned parts without wasting time and ensure on time delivery.

ISO 9001:2000 CERTIFIED MANUFACTURING FACILITY:

Our state of the art infrastructure is equipped with international quality compliant facilities that promise for the efficient performance without failing.

EXPERTISE IN ENGINEERING COMPLEX TURNING PARTS:

We have long back experience in the turning parts and hence qualified to carry out even complex turning parts with an ease.

OPTIMIZED PRODUCTION PROCESS:

We frequently test, calibrate every manufacturing facility along with the quality controlled manufacturing practices in order to obtain the best quality brass turned parts at the comparatively low prices.

EXTENSIVE QUALITY ASSURANCE

Before delivering any brass part to your doorstep, we carry out stringent quality checks through several testing methods to ensure quality competency of every manufactured brass part.

WE EXECUTE DIFFERENT SURFACE TREATMENTS

We apply manifold surface treatment for the finishing of the every brass turned parts and if we do not have suitable method, we associate with the authorized surface treatment service provider.

ON TIME DELIVERY

There is no need to wait long, while you approach us, as we are very strict to the timely delivery and for the same work deliberately to deliver at your doorstep before an outlined time frame.

THE BENEFITS OF OUR BRASS TURNED PRECISION PARTS

UNBEATABLE DIMENSIONAL ACCURACY

The pinpoint accuracy during the designing and fabrication is all going to give you a truly seamless quality range of the brass turned parts sharing the unbeatable amount of the dimensional accuracy

INNOVATIVE:

The significant versatility of the brass precision turned parts attributes multipurpose utility and hence makes it innovative, be it aerospace, electrical, hydraulic, automotive, brass inserts, etc.

ROBUST CONSTRUCTION

The brass material used in the construction imparts utmost strength and hence do not get affected while experiences high pressure and temperature.

LOW FRICTION COEFFICIENT

The low friction coefficient of our brass turned precision parts entitles high speed operations without wearing of parts and thusly increases the lifespan of the parts.

NO CORROSION

The brass is a combination of the copper and zinc that has excellent corrosion resilient property, reducing wear and tear of brass parts caused by corrosion as well as making it absolutely perfect for the corrosive environments too.

EXCELLENT HEAT RESISTANCE

The high heat resistance ability of the brass makes it the perfect material for the high temperature conditions and thereby our brass precision turned parts promise to outperform under the high temperature working conditions.

COST EFFECTIVE

The use of the CNC Machine and use of the standard manufacturing practices reduces the power consumption as well as the wastage of the material and hence we present our range of the precision turned brass parts at the most competitive rates.

News & Events

What is Brass Electrical Fittings ?

Brass Electrical Fittings have become an integral part of modern...

Read MoreWhat are the Components of Brass

Brass, an alloy renowned for its distinctive golden hue and...

Read MoreTypes of Brass Electrical Accessories

In the intricate realm of electrical systems, the significance of...

Read MoreWhat Are the Benefits of Using CNC Turned Parts?

Manufacturing processes have evolved significantly over the years, and one...

Read More